Leading the Way in Scale-Up Techniques and Educational Tools

At rm2technologies.com, we specialize in innovative training and scale-up techniques, leveraging 40 years of industrial and academic experience. Our comprehensive courses and resources empower professionals to enhance their skills, think out-of-the-box and succeed in process scale-up projects.

Pioneering Chemical Engineering with Decades of Expertise

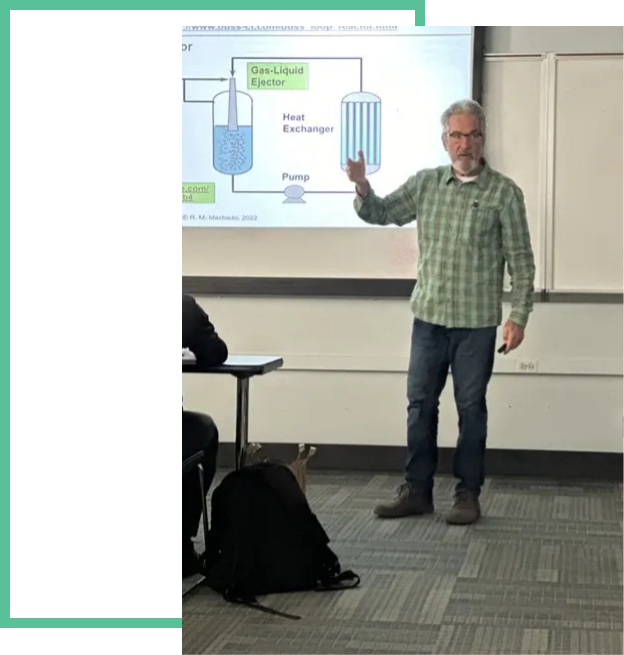

Reinaldo (Ray) Machado is an industrial consultant with 40 years of experience in chemical reaction engineering, having worked at Air Products and Chemicals, Versum Materials LLC, and most recently EMD Electronics, a subsidiary of Merck KGaA. Currently, he serves as a visiting scholar at Arizona State University, teaching the “Fundamentals of Scale-Up” course in the Chemical Engineering Department. Ray's extensive background includes contributions to the New Directions for Chemical Engineering (2022), where he discussed trends in production of chemicals for the electronic materials industry.

Development of Advanced Hydrogenation Technologies

While at Air Products and Chemicals, Ray’s teams pioneered semi-batch hydrogenation processes, establishing a new standard for hydrogenation technology, which was later implemented in chemical plants in Pasadena, Texas, and Nanjing, China.

Machado, R.M. “Increasing Productivity in Slurry Hydrogenation Processes.” Proceedings of the Fourth International Conference on the Scale-up of Chemical Processes, St. Helier Jersey, Channel Islands, England, September 2000 (sponsored by Scientific Update, E. Sussex, U.K.)

Machado, R.M. “Fundamentals of Mass Transfer and Kinetics for the Hydrogenation of Nitrobenzene to Aniline.” Proceedings of the First International Conference on the Scale-up of Chemical Processes, Brighton, England, September 1994 (sponsored by Scientific Update, E. Sussex, U.K.)

Machado, R.M., Heier, K.R., and Broekhuis, R.R. “Developments in Hydrogenation Technology for Fine-Chemical and Pharmaceutical Applications.” Curr. Opin. Drug Discovery Dev. 2001, 4, 745-755.

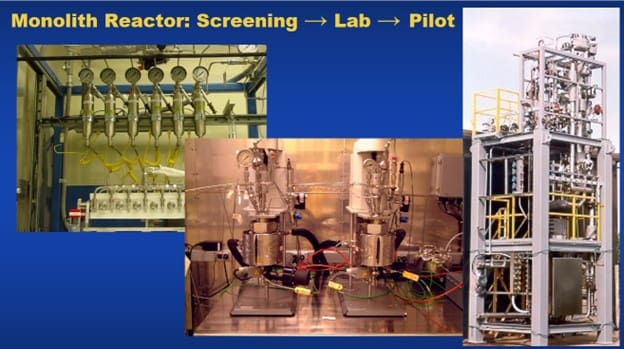

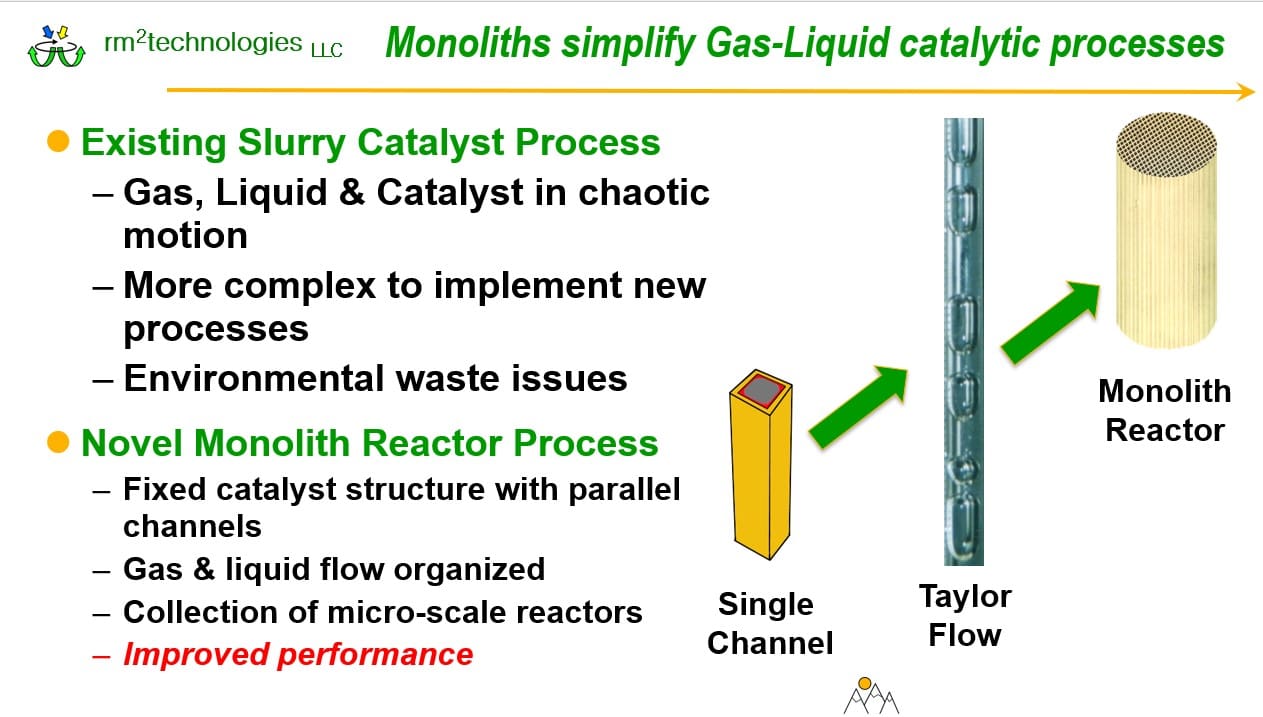

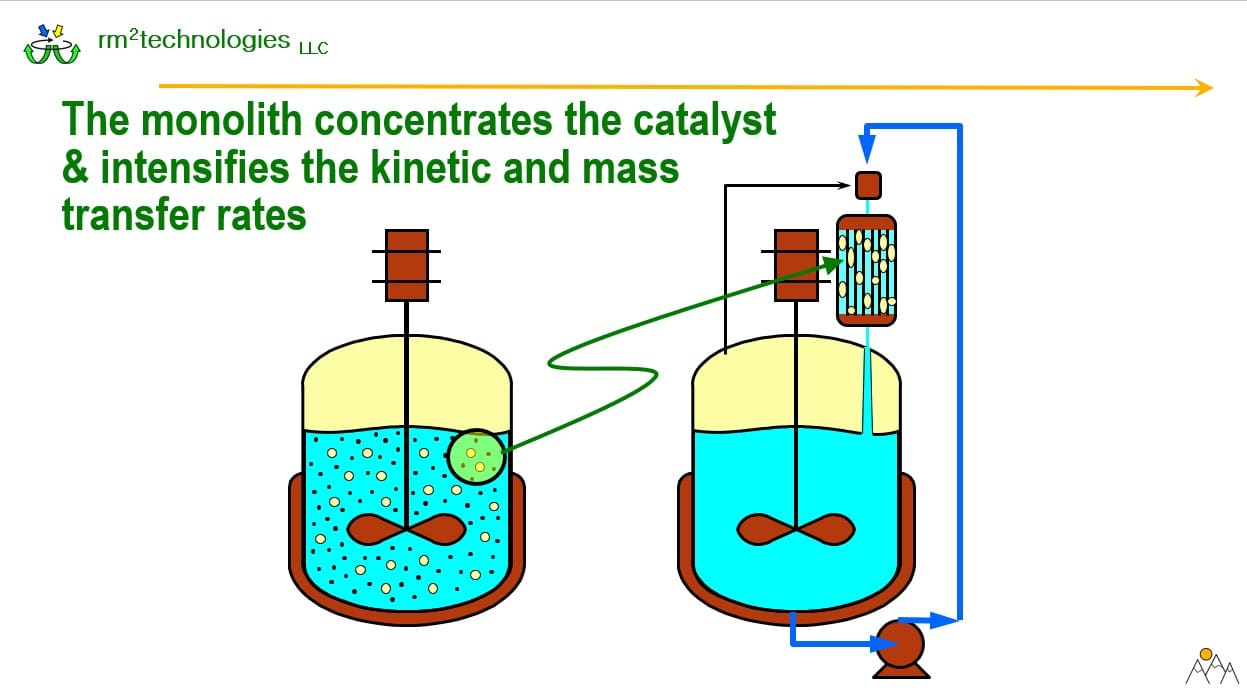

Leading the innovation of the MLR, Monolith Loop Reactor Ray and his team established a novel technology which allowed stirred tank reactors to be retrofitted with a monolith catalyst to replace problematic slurry catalysts.

(Patents: US6005143, US6479704, US6506361, US6610628, US6998507, US7074962, US7109378, US7595029)

Machado, R.M., Broekhius, R.R., Norquist, A.F., Roy, B.P. and Carney, S.R. “Applying Monolith Reactor for Hydrogenations in the Production of Specialty chemicals- Process and Economic Considerations”, Catalysis Today, 2005, 105, 305-317

Broekhuis, R.R., Machado, R.M., and Nordquist, A.F. “The Ejector-Driven Monolith Loop Reactor – Experiments and Modeling.” Catal. Today 2001, 69, 87-93

What Sets Us Apart

Our course is designed to challenge conventional thinking and inspire students to adopt rapid, creative problem-solving techniques.